I Stopped Shopping and Started Learning

The Friction That Forced a Change

The problem was not AI.

It was a fitted sheet that refused to stay on my mattress.

Every night, the corners popped off. Every morning, mild irritation. Not dramatic. Just persistent enough that it finally pushed me to do something about it.

I wanted three things:

-

-

- Sheets that actually fit

- Good quality

- A way to understand what “good quality” even means

-

I did not want to spend an hour on Amazon comparing reviews written by people I did not know, wondering who was sponsored and who was not.

So I opened ChatGPT.

That choice turned out to matter more than the sheets themselves.

What I Needed to Understand

My first prompt was not about brands or prices.

I asked:

What do cotton thread counts actually mean?

Not recommendations. Not shortcuts. Just education.

ChatGPT explained thread count, fiber length, weave types, and why a higher number is often marketing, not quality. It explained why percale feels different from sateen. Why long-staple cotton matters more than a label.

That short explanation replaced what used to take dozens of tabs and a lot of second-guessing.

More importantly, it changed how I approached the decision.

I was no longer browsing.

I was evaluating.

Context Changed Everything

Next, I added context.

I told ChatGPT that I had previously bought sheets from the W Hotel. I liked the feel. Crisp, durable, not soft to the point of flimsy.

Now the system understood my quality baseline.

From there, I asked:

- What brands match that level?

- What changes as price goes up or down?

- What trade-offs should I expect?

Instead of fifty tabs, I got a clear range of options.

Entry-level choices and what I would give up.

Mid-range options and what stayed solid.

Premium options and what I would actually be paying for.

I ended up buying sheets from The Company Store. Not because AI told me to. Because I finally understood why that choice made sense.

They fit.

They stay on.

They feel right.

Problem solved.

I did not shop faster. I understood faster.

AI did not give me a shortcut to a product.

It removed the work of assembling context.

This Was Not a One-Off

I realized this mattered because the same thing kept happening.

Car tires.

Home equipment.

Everyday problems where the old way meant searching, comparing, doubting, and manually stitching together information.

This shift did not happen overnight. It has been building for years. But experiences like this made it obvious.

My habit changed.

I no longer start by searching for products.

I start by understanding the problem.

Engineers are not skipping validation.

They are skipping friction.

What Actually Changed in How I Search

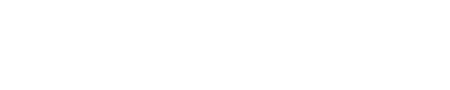

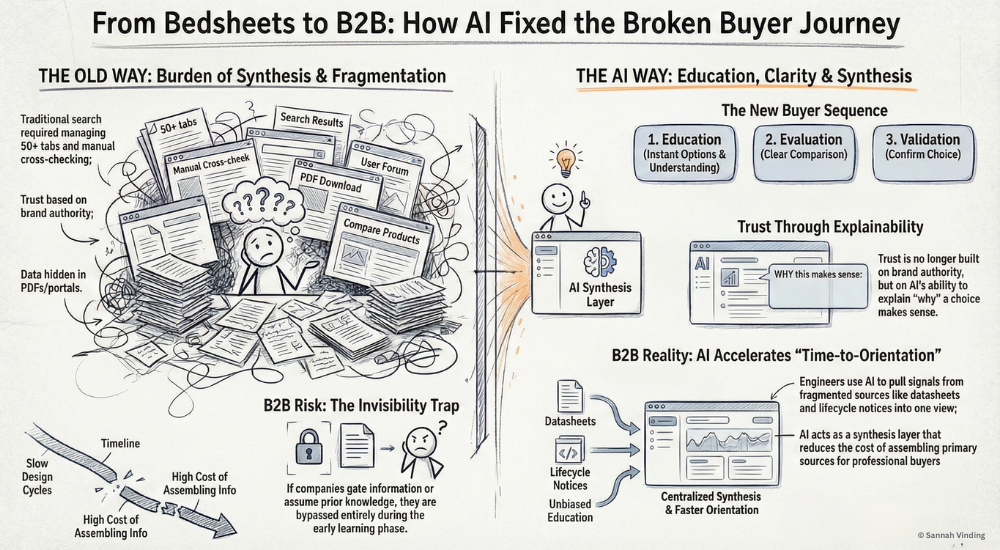

A few years ago, research looked like this:

- Search “best X”

- Open articles with unknown incentives

- Cross-check reviews

- Keep multiple tabs open

- Do the comparison myself

- Constantly question who to trust

The burden of trust and synthesis was entirely on me.

With AI, that burden shifts.

AI summarizes.

AI compares.

AI explains.

I still validate. I still check sources. But the first mile is accelerated.

Education happens first.

Evaluation comes second.

Validation comes last.

That sequence matters.

Why Engineers and Procurement Are Shifting to AI Search

This behavior change is not driven by novelty.

It is driven by structural pressure.

Engineers and procurement teams are not using AI because it is interesting. They are using it because the traditional way of finding information no longer scales.

Time Pressure Has Increased

Engineering work has always been complex. What has changed is timeline compression.

- Faster design cycles

- More frequent part substitutions

- Tighter qualification windows

- Higher expectations earlier in the process

Engineers are expected to make correct decisions sooner, with less iteration. Procurement is expected to validate availability, lifecycle, and compliance faster, often with incomplete data.

AI reduces time-to-orientation.

Not time-to-decision.

That distinction is critical.

Manufacturer Information Is Fragmented

Critical information is spread across:

- Datasheets

- PCNs

- Lifecycle notices

- Compliance portals

- Distributor pages

- PDFs behind registration walls

Individually, this makes sense. Collectively, it creates friction.

AI acts as a synthesis layer. It pulls scattered signals together so engineers can reason before they validate.

It does not replace primary sources.

It reduces the cost of assembling them.

Trust Has Shifted From Authority to Explainability

Engineers are trained skeptics.

They know which articles are sponsored.

They recognize SEO-driven comparisons.

They question “recommended” content.

AI feels different because:

- It explains before it recommends

- It allows follow-up questions

- It adapts as constraints are clarified

Trust is built through interaction, not claims.

“Trust didn’t come from a brand. It came from explanation.”

— Sannah Vinding

AI Matches How Engineers Think

Engineers reason in loops:

- Ask

- Test

- Refine

- Validate

AI mirrors that process.

Instead of restarting searches every time assumptions change, they iterate in place. That continuity matters.

Procurement Uses AI to Reduce Risk

Procurement teams use AI to:

- Identify alternatives

- Monitor lifecycle exposure

- Check availability signals

- Enter supplier conversations better prepared

This is not about replacing relationships.

It is about reducing blind spots early.

“If your product isn’t part of the early learning phase, it’s already late.”

— Sannah Vinding

What Electronics Companies Are Missing

Engineers are not abandoning manufacturer websites.

They are bypassing them in the early learning phase.

That phase is where preferences form.

That is where shortlists emerge.

That is where influence is established.

Too many electronics companies still:

-

- Assume prior knowledge

- Gate basic information

- Optimize for late-stage comparison

- Build sites that are hard to navigate or slow

AI fills that gap.

And when AI answers those early questions without you, you are not rejected. You are simply invisible.

The Real Risk: Invisibility in AI-Assisted Search

If nothing changes, the consequence is clear.

Companies that do not adapt become invisible in AI-assisted search.

They show up late.

They compete on availability.

They compete on price.

They let distributors or competitors define the narrative.

The winners will be the companies that:

-

-

- Explain clearly

- Publish usable knowledge openly

- Respect how engineers reason

- Reduce friction instead of adding it

-

AI did not convince me to buy bedsheets.

It removed friction.

That is the opportunity.

The fitted sheet problem was small.

The behavior shift behind it is not.

If you want to understand how B2B buying is changing, watch how you make decisions yourself. That future is already here.

Sannah Vinding

Engineer and Go-To-Market Leader

I’m an engineer and go-to-market leader with global experience across electronics and semiconductor businesses. I work at the intersection of product, engineering, and marketing, translating technical detail into clear positioning, usable content, and GTM systems that teams actually use. My focus is on practical execution, product clarity, and applying AI where it removes friction rather than adding noise.

If this resonated, read these next

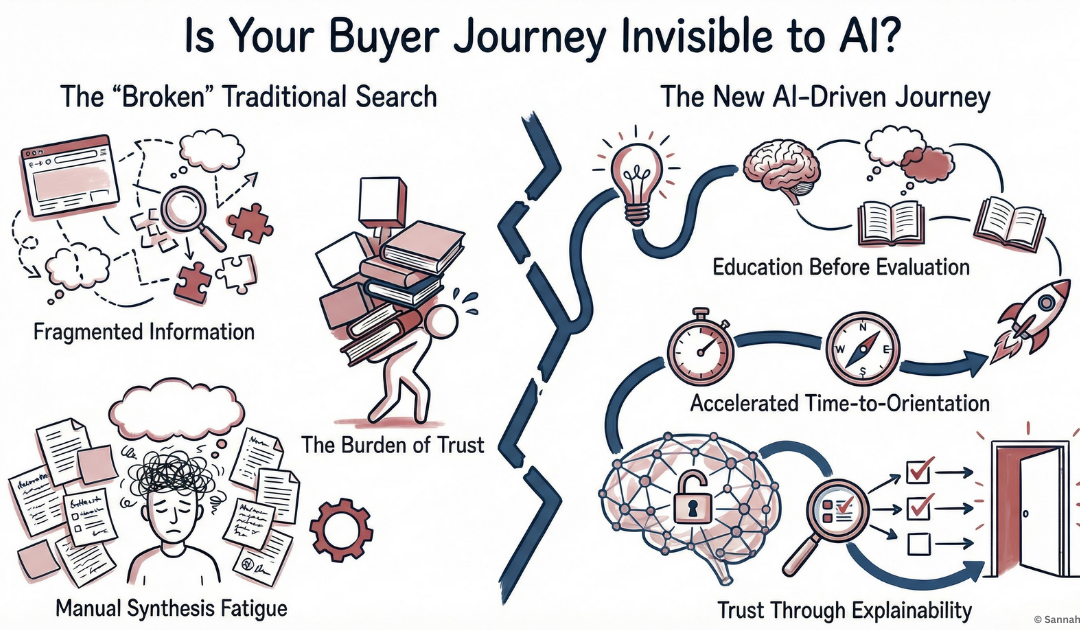

Why Electronics Companies Need an Engineering-Driven GTM Structure

Why go-to-market fails in electronics when it ignores engineering reality. Learn how engineering-driven GTM structures improve alignment, trust, and execution.

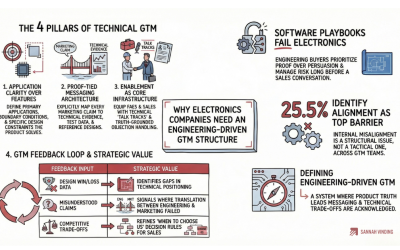

Why Manufacturing Marketing Is Struggling and What Leaders Must Do Next

Manufacturing marketing is falling behind. Learn why buyer behavior has shifted and what leaders must do to modernize strategy, improve alignment, and accelerate growth.

Follow for engineering-driven insight on AI, go-to-market strategy, and B2B growth in complex technical industries.